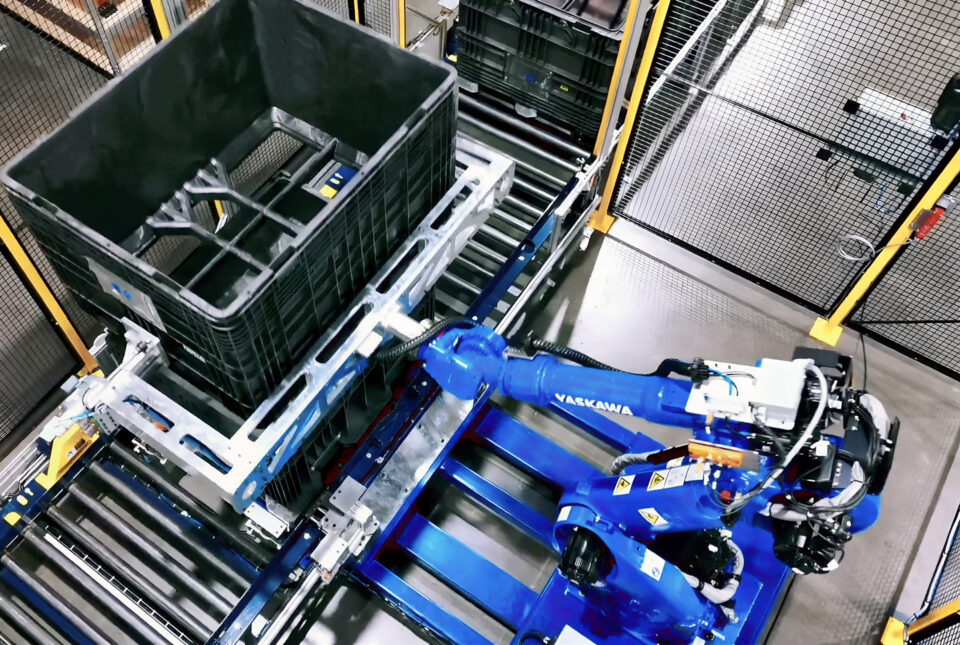

Custom Automation Solutions

We are a team of creative, driven engineers and fabricators.

Since 1984, we have proudly helped businesses across all industries turn ideas and concepts into AUTOMATION AT WORK. While today’s technology and tools are completely different, the same values still power our work. From design to delivery, we collaborate with you to build custom automation that meets your needs and exceeds your expectations.What We Do

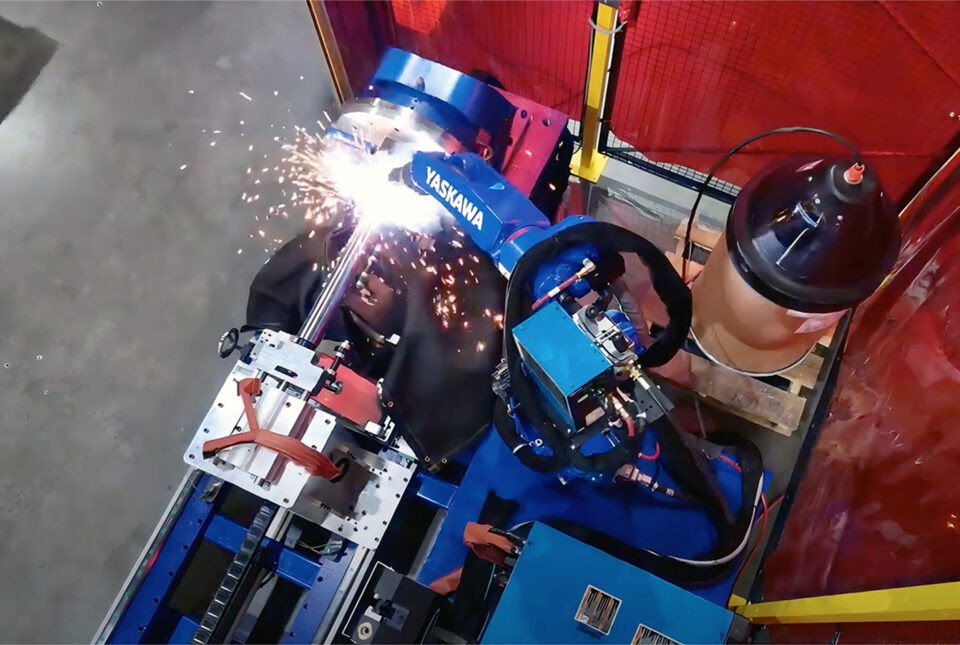

We provide innovative industrial automation solutions.

We concept, design, fabricate, assemble, test, and deploy every system, each uniquely designed and tailored to specific processes and environments. No plug and play options here—we offer a full-on partnership to ensure your project meets your goals and improves your operations. In cooperation with forward-thinking business owners, manufacturers, and innovators, we are redefining Automation At Work.What Sets Our Engineers Apart

At Set Automation, we work as one team to get every project done the right way on time. From creative collaboration with all stakeholders to clear communication throughout the process, our goal is always to deliver the best possible solution. With everything handled in-house, we treat each project with exceptional care and build every product with the quality craftsmanship we proudly stand behind.Does My Business Need Automation?

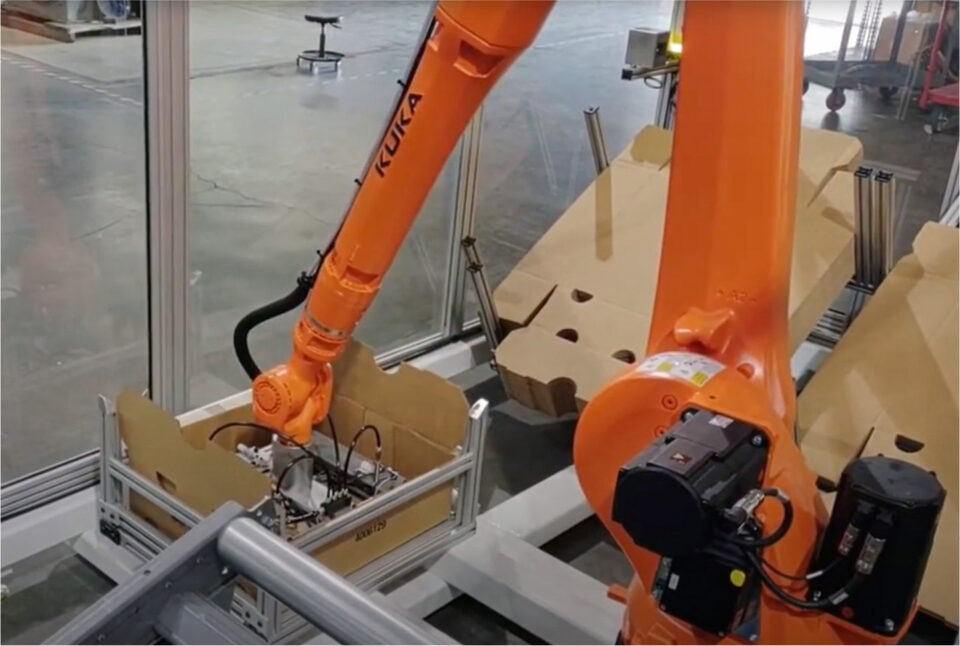

If you’re considering automation for your business, consider these questions:

Do you need to increase your production or scale your capacity?

Do you need to improve an inefficient process or reduce bottlenecks?

Do you need to to reduce defective parts or standardize quality?

Do you need to to eliminate a safety hazard or dangerous process?

If you answered yes to any of these questions, we would love to explore the best options to meet your needs. If you think AUTOMATION AT WORK would benefit you, click here to contact us..

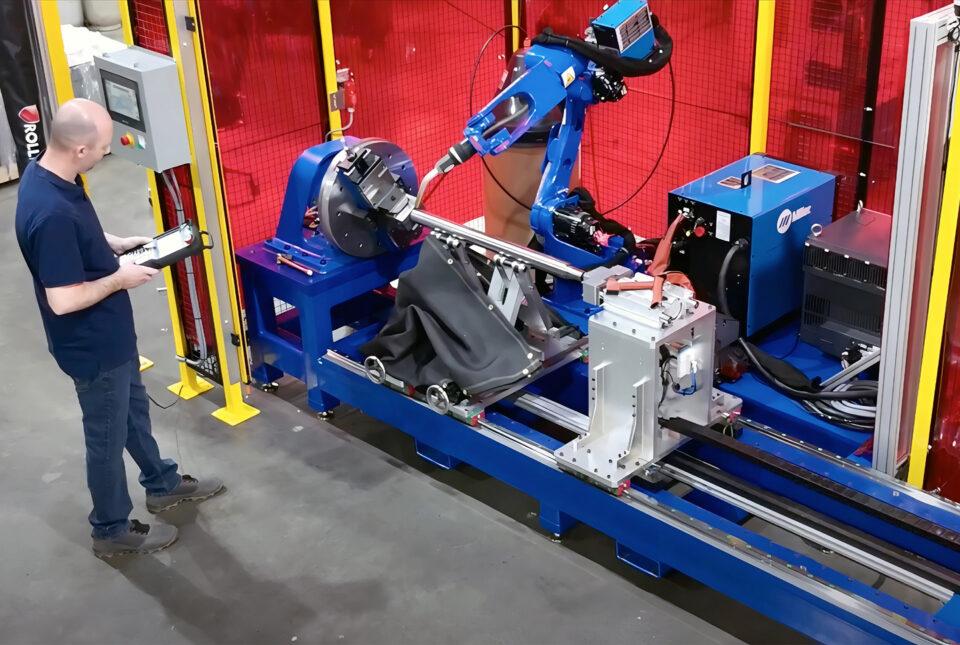

Our Services

Every system we build and integrate is designed to deliver meaningful outcomes to your business—increased product accuracy, improved cycle-time, increased safety, tighter process control, higher output, increased profits, and peace of mind. These positive outcomes, these intangibles, are what we care most about. Everything we create is in service of helping you meet your goals. Here’s how.