Our Process

Whether or not it’s your first automation project, getting started can be the most daunting part of the process. After all, a one-size-fits-all automation solution doesn’t exist. Your operation’s specific problem and need will determine which robots, mechanisms, sensors, and systems are ideal for the job. That’s where Set Automation comes in and thrives. We start with the basics to get your project done right… the first time.

Define

We listen to your specific needs and manufacturing challenges in order to understand and articulate your project goals. Then, we consider together how achieving these goals through the new system may impact other upstream and downstream processes.

Explore

Next, we present the various solutions that would help you meet project goals, keeping in mind your specific product output, mechanical requirements, quality control requirements, and budget.

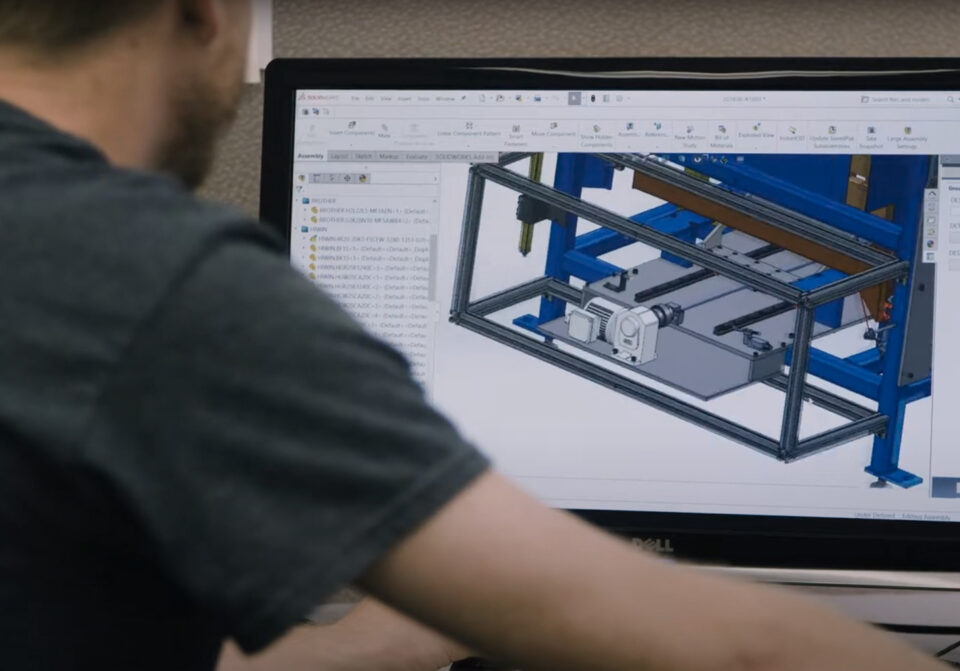

Design

Armed with a robust plan, our mechanical and controls engineers use advanced software to design your custom automation system.

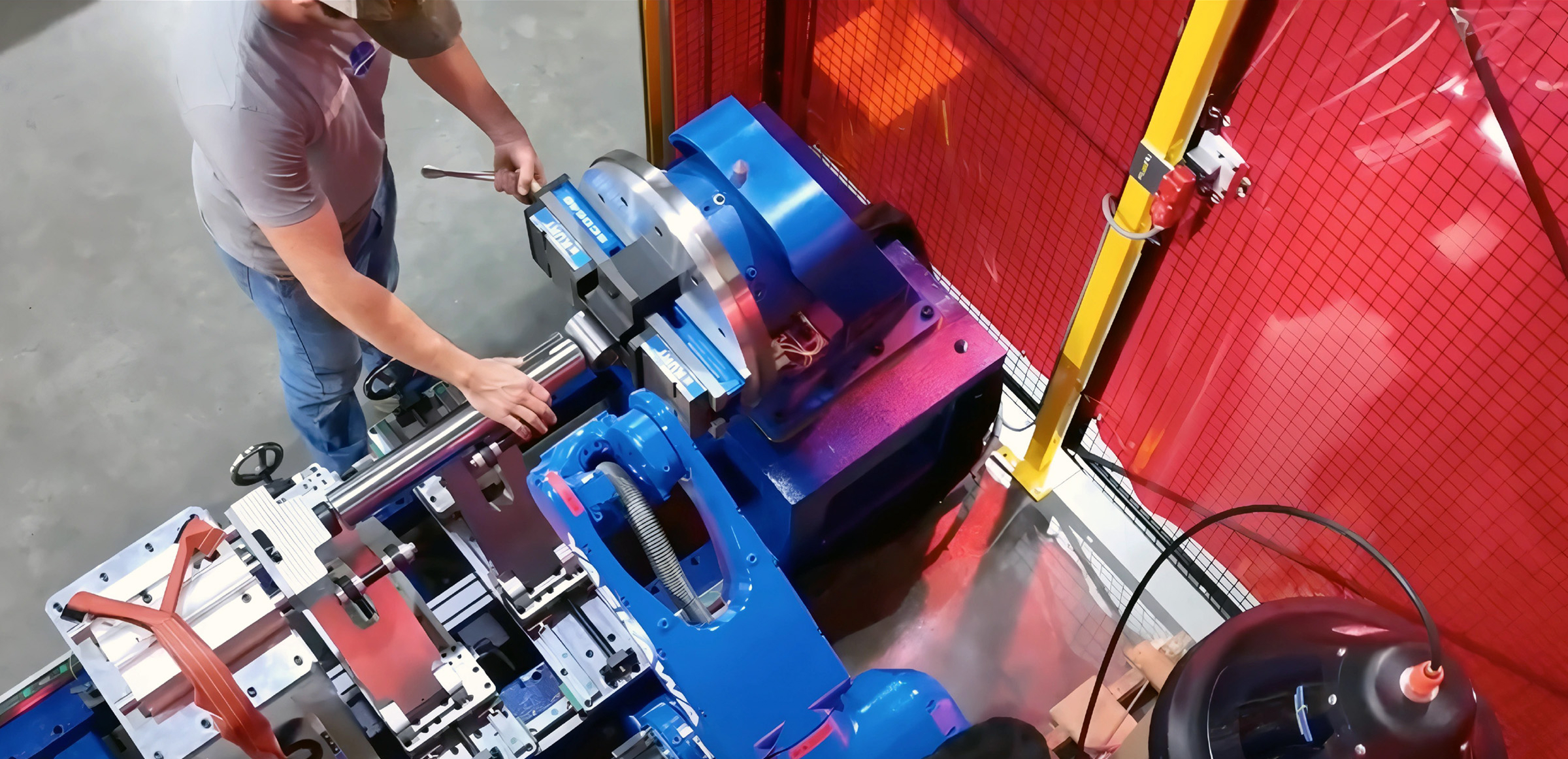

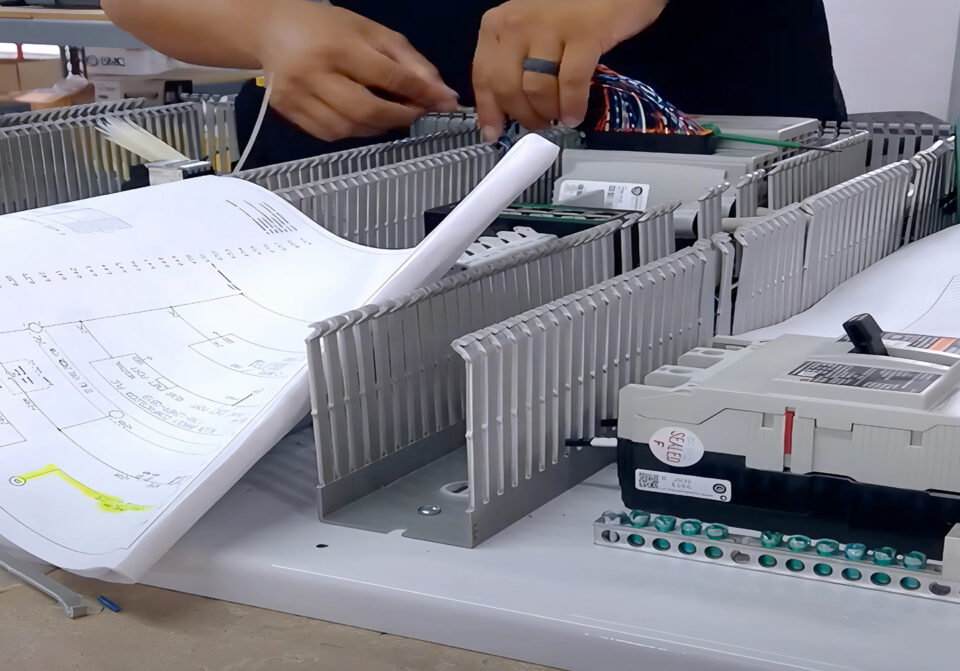

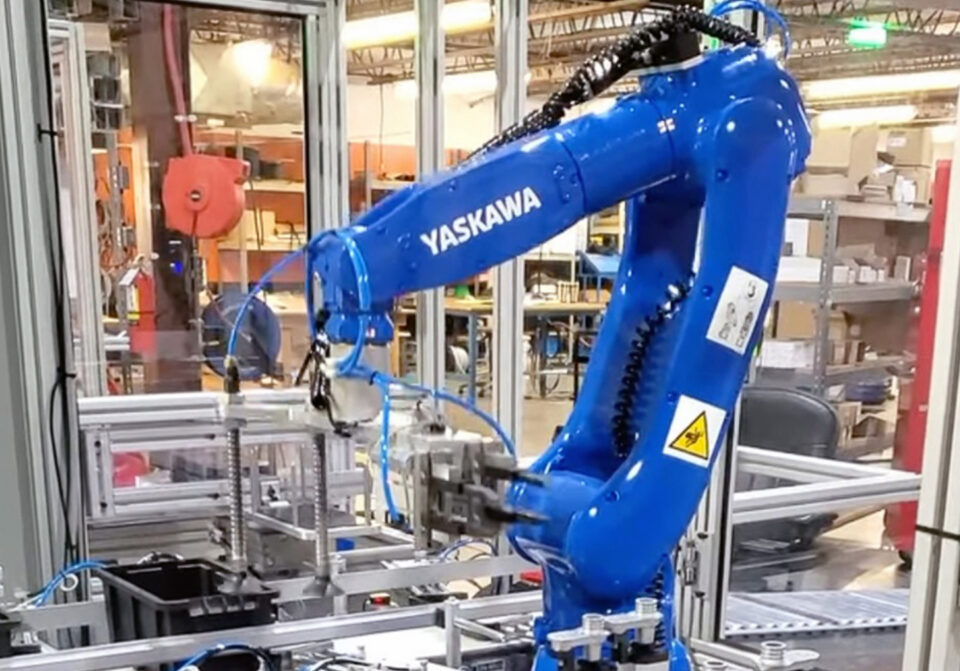

Build

Fabricators and craftsmen work alongside engineers in our design lab to create and construct your manufacturing system for maximum reliability.

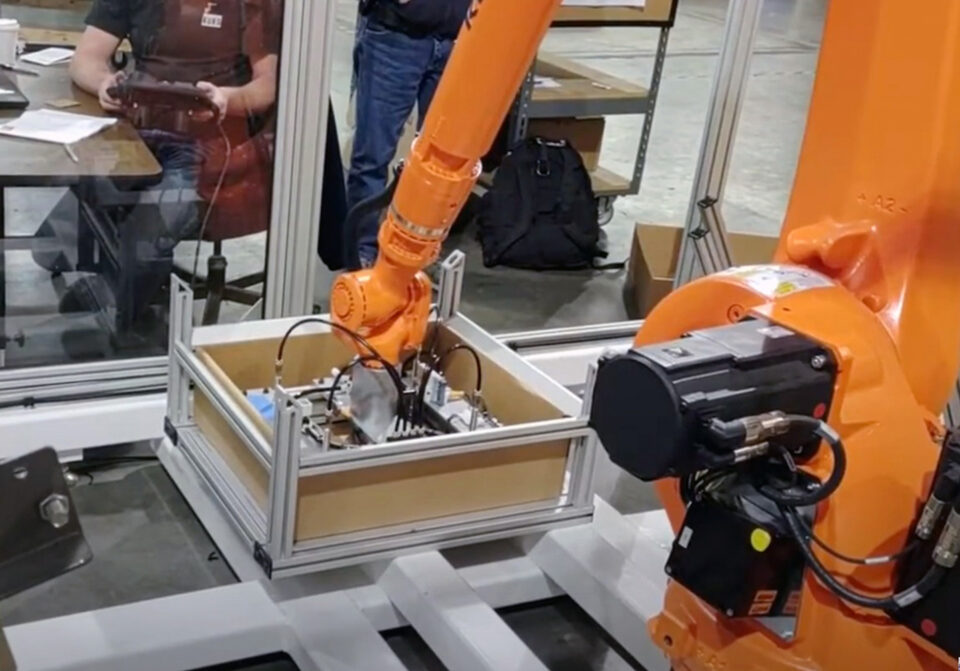

Test

Following assembly, the system enters a rigorous testing phase to validate performance. You are invited to our design lab at this stage to conduct Factory Acceptance Testing (FAT).

Deploy

Once your system has passed its final round of testing, our mechanical and controls engineers will deliver and assemble it on-site. Beyond installation, our team will also train your operators and complete final testing to ensure satisfaction.

Support

We are committed to fostering relationships. Once your system is up and running, we will continue to offer support. Whatever adjustment you need, we are here to keep your automation system running successfully.